Safeguarding Personnel and Assets

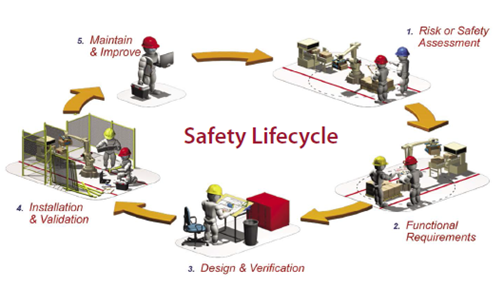

The primary goal of a risk assessment is to safeguard personnel from harm and protect valuable assets, including machinery and facilities. By meticulously identifying and evaluating hazards such as moving parts, electrical risks, chemical exposures, and ergonomic stressors, a risk assessment enables you to plan proactive measures to mitigate these dangers as you implement other steps in the safety lifecycle. For example, in the packaging industry, common hazards may include conveyors, blades that cut stretch wrap, heaters that cut and seal, pneumatic actuators that perform clamping and wrapping motions, and more. A proactive approach in the form of a risk assessment minimizes the likelihood of accidents, injuries, and occupational health issues, fostering a safer workplace environment.

Compliance and Regulatory Adherence

Adhering to regulatory standards is crucial for any industrial facility. Conducting regular risk assessments ensures that your operations meet and exceed regulatory requirements and industry consensus standards set forth by organizations such as OSHA, ANSI, and ISO. Compliance not only mitigates legal liabilities but also demonstrates your commitment to corporate responsibility and employee welfare.

Operational Continuity and Efficiency

Beyond safety considerations, risk assessments contribute to operational continuity and efficiency. By identifying potential hazards that could lead to equipment failures, production interruptions, or process inefficiencies, organizations can proactively implement measures to minimize downtime and optimize productivity. For instance, a company that is experiencing frequent downtime due to jams on a packaging line may think that they must employ lockout/tagout (LOTO) procedures during each jam incident. However, a safety risk assessment may recommend an alternative protective measure such as an interlock door to clear the jam without requiring the use of LOTO. This proactive safeguarding approach helps maintain smooth operations and enhances overall business performance.

Cost-Effectiveness and Risk Management

Effective risk assessments are integral to sound risk management practices. By prioritizing risks based on severity and likelihood, organizations can allocate resources more efficiently towards implementing appropriate controls and mitigations. This strategic allocation not only reduces potential financial losses from accidents, fines, and litigation but also enhances the return on investment in safety measures by targeting areas with the highest impact.

The Risk Assessment Process Flow Chart (ANSI B11.0)

The cornerstone of our risk assessment methodology aligns closely with the guidelines issued by ANSI B11.0, which provides a structured framework for assessing machinery-related hazards. Here’s a high-level overview of the Risk Assessment Process Flow Chart:

- Preparation:

- Define Scope: Identify the boundaries and objectives of the risk assessment, including the specific machines and processes to be evaluated.

- Assemble Team: Formulate a multidisciplinary team comprising experts in engineering, safety, maintenance, and operations to ensure comprehensive insights.

- Hazard Identification:

- Identify Hazards: Conduct a systematic review and inspection of machinery to pinpoint potential sources of harm, such as moving parts, electrical hazards, or ergonomic risks.

- Document Hazards: Document each identified hazard along with its location, nature, and potential consequences on personnel and equipment.

- Risk Estimation:

- Evaluate Risks: Assess the likelihood and severity of each identified hazard using standardized risk assessment matrices or algorithms.

- Assign Risk Levels: Employ a risk rating methodology to categorize hazards based on their potential impact, such as low, medium, or high risk. This step helps prioritize mitigation efforts.

- Risk Evaluation:

- Determine Risk Acceptability: Compare evaluated risks against established risk tolerance criteria and regulatory requirements.

- Recommend Mitigations: Propose risk control measures and safeguards to reduce identified risks to an acceptable level.

- Risk Reduction:

- Implement Controls: Implement engineering controls, administrative controls, and/or personal protective equipment (PPE) to mitigate identified risks effectively.

- Verify Effectiveness: Validate the implementation of risk control measures through testing, validation, and verification procedures.

- Documentation and Review:

- Document Findings: Record all assessment results, including hazard registers, risk assessments, and implemented controls, in a comprehensive report.

- Periodic Review: Establish protocols for periodic review and reassessment of risks to account for changes in machinery, processes, or regulations.

Risk Rating Methodologies

There are several different types of risk assessment methodologies. Rockwell Automation employs robust methodologies to ensure accuracy and consistency in risk evaluation:

- Severity Assessment (Degree of possible harm): Quantifies the potential consequences of a hazard on personnel, equipment, and production. For example, potential hazards to personnel include the impact of a scratch or bruise versus a broken bone or worse.

- Likelihood of Occurrence: Assesses the probability of a hazard causing harm based on factors such as approach speeds, awareness, data (event history), or processes.

- Frequency of exposure: How often are personnel, maintenance technicians, or other persons exposed to the hazard? The frequency of exposure can vary from constant, hourly, daily, weekly, monthly, or annually.

- Number of persons: How many people may be affected by the hazard or hazardous event.

Why Choose Rockwell Automation for Your Risk Assessments?

We bring decades of expertise in industrial automation and safety to every risk assessment project. Our commitment to excellence helps ensure that your facility not only meets regulatory requirements but also achieves a culture of safety excellence. By leveraging our comprehensive risk assessment services, you can:

- Enhance safety: Identify and mitigate hazards proactively to create a safer working environment for your personnel.

- Optimize operations: Minimize downtime and improve productivity by addressing potential risks before they escalate.

- Ensure compliance: Align with industry standards and regulatory requirements to avoid penalties and uphold corporate responsibility.

Partnering with Rockwell Automation for your risk assessments means investing in the safety and efficiency of your operations. Our structured approach, guided by ANSI and ISO standards, is supported by advanced risk rating methodologies and empowers you to mitigate risks effectively and sustainably. Contact us to embark on a journey towards safer, more productive industrial practices with confidence.